What is Nylon PA 12-Polyamide 12 (PA 12)

The Nylon PA 12-Polyamide 12 (PA 12) (plastic) things printed through Sculpteo are produced from a fine polyamide powder, more commonly known as plastic. Nylon PA 12-Polyamide 12 (PA 12) is great for both seasoned specialists as well as beginning developers due to its high precision and also affordable. The good mechanical buildings of this nylon product will be for advanced additive manufacturing tasks and can even substitute shot molding plastics. Thanks to its low concentration of amides, it has small wetness absorption, which suggests a good resistance to chemicals.

The technological properties of this product additionally depend on the density of the 3D design you have actually produced. Our 3D printing plastics have different elastic modulus measurements. You will locate much more technical data regarding tensile stamina, flexural stamina, or deflection temperature level in the technical sector of this product web page.

Unfinished, this material is white, granular, and also rather permeable when it is directly appearing of our industrial 3D printers- these choices can be additional fine-tuned with Sculpteo’s in home polishing and coloring processes.

Applications: What can you acheive with this product?

This material is well utilized in the 3D printing sector, as it enables quick prototyping along with finished customer products. Prototyping with Nylon PA12 (plastic) is a great option since this 3D printing product is cheaper and also faster than other procedures. You just have to change your layout with your 3D software application as well as make new versions. It is a common 3D printing product made use of for numerous applications as well as has really good quality standards.

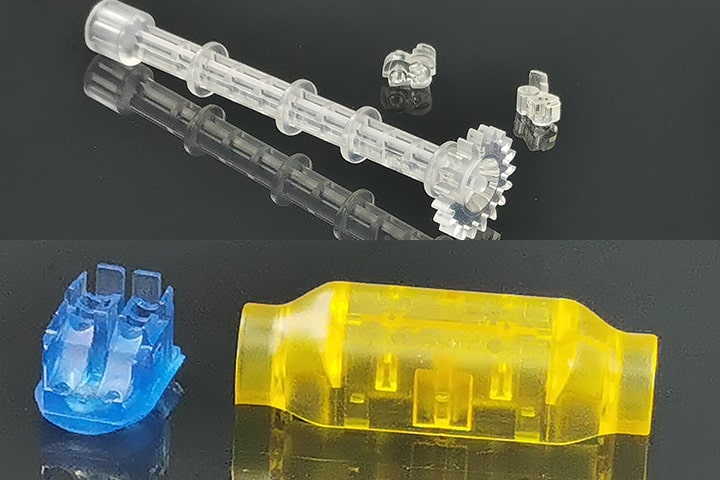

The biocompatibility of this 3D printing material enables to 3D print items for clinical applications, such as 3D published prostheses. The high abrasion resistance of this material likewise allows the production of movable component connections such as gears or hinges.

This material has an excellent UV resistance, making it appropriate to develop parts that are versatile to every climate.

Prices.

The printing rate of your style is computed automatically the minute it is put online. As you change your object (transforming dimension, using set control or hollowing attribute, and so on) you will certainly keep in mind that the price changes immediately. The pricing is based upon a collection of elements, consisting of overall volume, object size, and bounding box– to name a few.

White, rugged Nylon PA 12-Polyamide 12 (PA 12) (plastic) has the quickest reverse time of our products. Polishing, painting as well as particularly big items can expand the processing time. The estimated shipping time is also computed instantly as the things is posted.

Delivery time must be included in refining time and depends on the shipment option you select.

You will have the choice among three shipment alternatives: economical, typical, express. Your selection will necessarily affect the cost of your order.

What regarding the Nylon PA 12-Polyamide 12 (PA 12) 3D printing process?

Sculpteo makes use of a layer by layer procedure called Careful Laser Sintering (SLS) for all Nylon polyamide 12 (plastic) prints.

The Discerning Laser Sintering modern technology makes use of an extremely certain laser that sinters slim layers of polyamide PA12 powder with each other one layer each time. After each round of lasering, the printing bed is lowered as well as one more layer of powder is equally brushed up across the top for an additional round of sintering. This procedure is duplicated at a layer elevation of either 100– 120 µm or 60 µm till the object is completed.

Finishings readily available.

There are several coloring and also completing alternatives readily available with Sculpteo consisting of dyeing, polishing, paint, chemical smoothing, and our special Shade Touch and Shade Resist processes.

Completing alternatives readily available after the additive manufacturing process:.

Raw: Sandblasted but unpolished, the surface area stays somewhat harsh, it is the most economical option, best for your fast prototyping procedure.

Sleek: Sleek via mechanical sprucing up, smoother to touch, layers still rather noticeable on rounded objects.

Chemical Smoothing: Smoothed through a physicochemical process, the objects finished with our unique Smoothing Beautifier procedure have a shiny surface. This brand new process aims at closing the void in between the surface high quality of shot molded components as well as 3D printed parts. The process brings smoothing to every section of the things as well as functions by securing the porous surface of your Nylon PA 12-Polyamide 12 (PA 12)(plastic) part.

This coating is recommended for organic shapes, porcelain figurines, however likewise for electronic enclosures. The Smoothing Beautifier supplies a surface area finish that is as smooth as injection-molded surface areas. Due to the nature of this patented process, the outcome might vary from one component to an additional. The physicochemical reaction can undoubtedly induce some improvement on the component such as minor geometrical changes or a loss of information. Designs that include very elaborate geometries, hollowed components or sharp angles or sides can endure appearance transformations.

Colored with Color Resist coating: A dyeing finish with a matte look that stands up to friction and also enables more regular color in between different production sets.

Dyed with Shade Touch surface: This coating is offered just after calling our Sales team for customizing your order. With this coloring completing your 3D published component gets a satin appearance. It endures daily handling as well as is the excellent finish for components that are revealed to external problems, damaging as well as scrubing.

What is Nylon PA 12-Polyamide 12 (PA 12)

10

Jul