ULTEM™ RESIN FAMILY OF HIGH HEAT SOLUTIONS

ULTEM™ resin is a Polyetherimide (PEI), which offers a unique combination of thermal performance, high modulus, dimensional stability, near-infrared transparency, and non-halogenated FR for a wide range of demanding applications. EXTEM™ resin is well-suited for applications that require a higher thermal performance, such as co-packaged optical components. SILTEM™ resin is an easy extrudable amorphous copolymer with no intentionally added PFAS for potential use in applications such as high-performance wires and cables.

High temperature resistant resins and compounds are also available under LNP™ Compounds and PC Copolymer Resins and NORYL™ Resins families.

ULTEM™ RESIN FAMILY OF HIGH HEAT SOLUTIONS

EXTEM™ Resin

SILTEM™ Resin

ULTEM™ Resin

7 EXTEM™ RESIN

Grades Available: 7

Available in: Europe, Asia, Americas

GENERAL INFORMATION

DESCRIPTION

The new EXTEM™ Resin portfolio of amorphous thermoplastic polyimide (TPI) and polyetherimide (PEI) resins offers a powerful combination of outstanding elevated thermal resistance up to 280 °C Tg; high strength, stiffness, and creep performance up to 230 °C, broad chemical resistance including chlorinated solvents; and eliminates the draw-backs of semi-crystalline materials, imidized thermosets, and competitive amorphous thermoplastics which can require post-molding curing or crystallization. In addition, EXTEM resin is inherently flame-retardant without the use of halogenated additives that can pose an environmental risk.

EXTEM is available in transparent and opaque custom colors, as well as glass filled grades. In the near future, EXTEM with additional fillers will be available through SABIC LNP™ Compounds to provide wear resistance performance, electrostatic dissipative properties, enhanced dimensional stability, and more. Plus, EXTEM resin portfolio is extremely versatile allowing SABIC to design products that can offer design engineers exceptional flexibility and freedom.

BENEFITS

LONG-TERM HEAT RESISTANCE

Excellent stability of physical and mechanical properties at elevated temperatures thanks to high glass transition temperature of up to 280 °C. Available with relative thermal indices (RTI) higher than 200 °C (preliminary).

STRENGTH AND STIFFNESS

Outstanding strength, stiffness and creep resistance with predictable performance up to 230 °C (preliminary). EXTEM XH resin is approximately 50% stronger at 170 °C than ULTEM resin. Unfilled, transparent grades are equal in strength to other thermoplastics with opacifying fillers.

DIMENSIONAL STABILITY

Among the most dimensionally stable thermoplastics available, offering predictability over a broader temperature range exceeding 200°C. Filled grades offer exceptionally high-tolerance dimensional capabilities.

ENVIRONMENTAL STRESS & CRACKING RESISTANCE

Unlike most other amorphous thermoplastics, EXTEM resins retain strength and resist stress cracking when exposed to automotive and aircraft fluids, aliphatic hydrocarbons, alcohols, acids as well as chlorinated solvents such as methylene chloride.

FLAMMABILITY, SMOKE GENERATION AND TOXICITY

Inherently flame-retardant without the use of halogenated additives, which can pose an environmental risk. EXTEM resin is exceptionally difficult to ignite, with a limiting oxygen index (LOI) of 45% (preliminary). EXTEM resin is expected to retain the UL performance and flame, smoke and toxicity strengths of ULTEM resin.

PROCESSABILITY

EXTEM resin can be processed in conventional drying and injection molding or extrusion equipment capable of running ULTEM resin and other high heat thermoplastics. EXTEM resin can be film and profile extruded, thermoformed, extrusion blow molded, extruded into stock shapes, and injection molded. Flowability can be tailored to meet customer applications through product and processing design and flows similar to ULTEM resins.

RH1016UCL

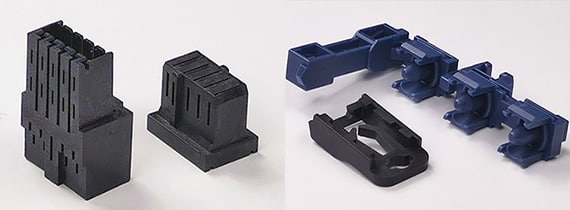

EXTEM RH1016UCL resin is an unreinforced amorphous thermoplastic polyimide (TPI) resin that may offer a high glass transition temperature (Tg) of 279°C. Features are excellent mechanical, electrical and dimensional properties up to high temperatures. The material has good near-IR transparency and a high refractive index making it an excellent candidate for SMT at JEDEC standard temperature of 260°C needing injection moldable optical lenses and connectors. The material is RoHS compliant and the natural, uncolored, material is halogen free according to standards IEC 61249-2-21, IPC 4101E and JEDEC JS709B. For colored variants compliance needs to be checked case by case.

VH1003

Transparent, Thermoplastic Polyimide (TPI) resin with a glass transition temperature (Tg) of 247C. This product has thin wall FR capability and has a UL94 V0 listing. This material is RoHS compliant and also halogen free according VDE/DIN 472 part 815.

VH1003F

Transparent, Thermoplastic Polyimide (TPI) resin with a glass transition temperature (Tg) of 247C. This product has thin wall FR capability and has a UL94 V0 listing. This material is RoHS compliant and also halogen free according VDE/DIN 472 part 815. Global Food Contact Approvals.

VH1003M

Transparent, Thermoplastic Polyimide (TPI) resin with a glass transition temperature (Tg) of 247C. Internal mold release. This product has thinwall FR capability and has a UL94 V0 listing. This material is RoHS compliant and also halogen free according VDE/DIN 472 part 815.

VH1003P

Transparent, Thermoplastic Polyimide (TPI) resin with a glass transition temperature (Tg) of 247C. Powder version of VH1003.

XH1015UCL

EXTEM XH1015UCL resin is an unreinforced amorphous thermoplastic polyimide (TPI) resin that may offer a high glass transition temperature (Tg) of 267°C. Features are excellent mechanical, electrical and dimensional properties up to high temperatures. The material has good near-IR transparency and a high refractive index making it an excellent candidate for injection moldable optical lenses and connectors. EXTEM resin XH1015UCL can withstand SMT soldering temperatures up to 245˚C. For a near-IR transparent solution with SMT at JEDEC standard temperature of 260°C please consult our EXTEM™ resin RH1016UCL. The XH1015UCL is RoHS compliant and the natural, uncolored, material is halogen free according to standards IEC 61249-2-21, IPC 4101E and JEDEC JS709B. For colored variants compliance needs to be checked case by case.

XH2315

EXTEM XH2315 Resin is a reinforced, 30% glass fiber filled amorphous thermoplastic polyimide resin that may offer a extremely high glass transition temperature (Tg of 267°C). Features are excellent mechanical, electrical and dimensional properties up to highest temperatures. The material may offer very good chemical resistance for an amorphous material and is inherently flame retardant offering UL94 V0 ratings at 0.75 mm and V0,5VA at 1.0 mm and 1.5-1.65 mm. The material is RoHS compliant. The base material is transparent amber colored and available in natural and black color.