Fluoroplastics: an outstanding representative of high-performance polymers

- PTFE: PolyTetraFluoroEthylene

- FEP: Fluorinated Ethylene Propylene

- PFA: PerfluoroAlkoxy

- PVDF: PolyVinylidene DiFluoride

- PCTFE: PolyChloroTriFluoroEthylene

- ECTFE: Ethylene ChloroTriFluoroEthylene

- PVF: PolyVinyl Fluoride

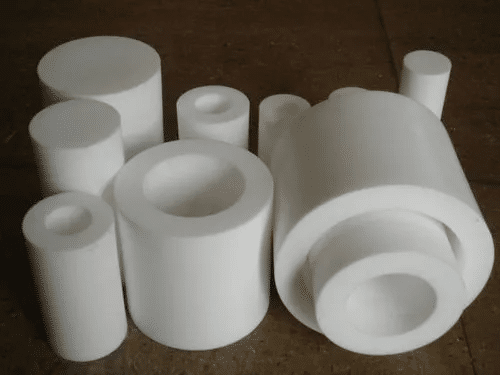

Fluoroplastie is a type of high-performance plastic made of fluororesin, including polytetrafluoroethylene (PTFE), tetrafluoroethylene-ethylene copolymer (PCTFE), tetrafluoroethylene-hexafluoropropylene copolymer (FEP) , chlorotrifluoroethylene-ethylene copolymer (PVDF), PFA, ECTFE, PVF and many other varieties. These fluoroplastics exhibit excellent performance in many fields and are widely used. Next, we will have an in-depth understanding of the performance characteristics, product applications, and manufacturers of some famous brands and models of these fluoroplastics.

Performance features:

High temperature resistance: Fluoroplastics have excellent high temperature resistance and can maintain their stability under extreme temperature conditions, making them ideal for high temperature environments.

Chemical inertness: Fluoroplastics exhibit excellent chemical stability and high corrosion resistance to acids, alkalis and other chemical substances, making them widely used in the chemical industry.

Electrical insulation: These materials have excellent electrical insulation properties and are suitable for the electrical and electronic industries. They can be used to manufacture cable insulation layers, electronic components, etc.

Low friction coefficient: Fluorine plastic has a smooth surface and low friction coefficient, which gives it unique advantages in lubrication and is widely used in bearings, seals and other fields.

Applications:

Polytetrafluoroethylene (PTFE): Due to its excellent chemical resistance and low friction coefficient, PTFE is often used to manufacture seals, valve seats, conduits, etc., and is also widely used in food processing, medical equipment and other fields.

Tetrafluoroethylene-ethylene copolymer (PCTFE): With excellent gas barrier properties and chemical stability, PCTFE is often used to manufacture high-performance films, chemical valves, cable insulation, etc.

Tetrafluoroethylene-hexafluoropropylene copolymer (FEP): It has superior thermoplasticity and transparency and is often used in the manufacture of cable sheaths, coatings, pipes, etc.

Chlorotrifluoroethylene-ethylene copolymer (PVDF): It has good high temperature resistance and chemical stability and is widely used in electrical, electronics, construction and other fields.

Manufacturers of famous brands and models:

PTFE: DuPont is the world’s leading manufacturer of PTFE, and its brand Teflon is widely used in various fields.

PCTFE: Manufacturers with high-quality PCTFE products include Honeywell and others.

FEP: DuPont is one of the major manufacturers of FEP, and its brand Teflon FEP is widely recognized in electronics, chemical industry and other fields.

PVDF: Manufacturers with excellent PVDF products include Arkema, Solvay, etc., and their brands Kynar and Solef are highly respected in the market.

To sum up, fluoroplastics have achieved remarkable application results in many fields with their excellent performance characteristics, and each variety has its unique advantages in specific fields. When choosing fluoroplastics, in addition to paying attention to product performance, choosing well-known brands and reliable manufacturers is also the key to ensuring product quality.

User

Please expand on this

ChatGPT

Fluoroplastics: an outstanding representative of high-performance polymers

Fluoroplastie is a type of high-performance plastic made of fluororesin, including polytetrafluoroethylene (PTFE), tetrafluoroethylene-ethylene copolymer (PCTFE), tetrafluoroethylene-hexafluoropropylene copolymer (FEP) , chlorotrifluoroethylene-ethylene copolymer (PVDF), PFA, ECTFE, PVF and many other varieties. These fluoroplastics exhibit excellent performance in many fields and are widely used. Next, we will have an in-depth understanding of the performance characteristics, product applications, and manufacturers of some famous brands and models of these fluoroplastics.

Performance features:

High temperature resistance: Fluoroplastics have excellent high temperature resistance and are able to maintain their stability under extreme temperature conditions, making them ideal for high temperature environments. This makes fluoroplastics widely used in applications in high-temperature environments such as aerospace and automotive industries.

Chemical inertness: Fluoroplastics exhibit excellent chemical stability and high corrosion resistance to acids, alkalis and other chemical substances, making them widely used in the chemical industry. In corrosive environments, fluoroplastics can maintain stable performance and extend service life.

Electrical insulation: These materials have excellent electrical insulation properties and are suitable for electrical and electronic industries. In the manufacturing of electronic components, fluoroplastics can provide reliable insulation protection and ensure the safe operation of equipment.

Low friction coefficient: Fluoroplastic has a smooth surface and low friction coefficient, giving it unique advantages in lubrication. This makes fluoroplastics excellent in manufacturing bearings, seals and other applications that require low friction.

Applications:

Polytetrafluoroethylene (PTFE): Due to its excellent chemical resistance and low coefficient of friction, PTFE is often used in the manufacture of seals, valve seats, conduits, etc. At the same time, its application in food processing, medical equipment and other fields cannot be ignored to ensure product hygiene and safety.

Tetrafluoroethylene-ethylene copolymer (PCTFE): With excellent gas barrier properties and chemical stability, PCTFE is often used to manufacture high-performance films, chemical valves, cable insulation, etc. Its applications in gas delivery and electrical fields help improve product performance.

Tetrafluoroethylene-hexafluoropropylene copolymer (FEP): It has superior thermoplasticity and transparency and is often used in the manufacture of cable sheaths, coatings, pipes, etc. FEP’s transparency makes it ideal for use in the optical field, where it is used to make optical lenses, window coatings, and more.

Chlorotrifluoroethylene-ethylene copolymer (PVDF): It has good high temperature resistance and chemical stability and is widely used in electrical, electronics, construction and other fields. PVDF plays an important role in solar cells, cable insulation, etc.

Manufacturers of famous brands and models:

PTFE: DuPont is the world’s leading manufacturer of PTFE, and its brand Teflon is widely used in various fields.

PCTFE: Manufacturers of high-quality PCTFE products include Honeywell, whose products are often used in high-demand gas valves and electrical insulation fields.

FEP: DuPont is one of the major manufacturers of FEP, and its brand Teflon FEP is widely recognized in electronics, chemical industry and other fields. Other manufacturers such as Daikin also have a certain market share in the FEP field.

PVDF: Manufacturers with excellent PVDF products include Arkema, Solvay, etc., and their brands Kynar and Solef are highly respected in the market. These brands of PVDF are widely used in construction, electrical and other fields.

To sum up, fluoroplastics have achieved remarkable application results in many fields with their excellent performance characteristics, and each variety has its unique advantages in specific fields. When choosing fluoroplastics, in addition to paying attention to product performance, choosing well-known brands and reliable manufacturers is also the key to ensuring product quality. Whether in the chemical industry, electronics, medical or construction fields

To purchase fluorine Plastic, visit the E-polymer Plastic Gtoup website:www.e-polymer.com

For custom or machine processed fluoroplastic plastic parts, please visit the E-lasrics website:www.e-lastics.com

To buy plastic masterbatches and additives: visit the Mt-color website:www.mt-color.com