PPA (polyphthalamide):

Unraveling the Strengths of PPA (Polyphthalamide): A Comprehensive Guide

Introduction: In the realm of advanced polymers, Polyphthalamide (PPA) stands tall as a high-performance material, showcasing exceptional mechanical properties and versatility. This comprehensive guide aims to delve into the intricacies of PPA, shedding light on its unique characteristics, applications, and why it has become a key player in various industries.

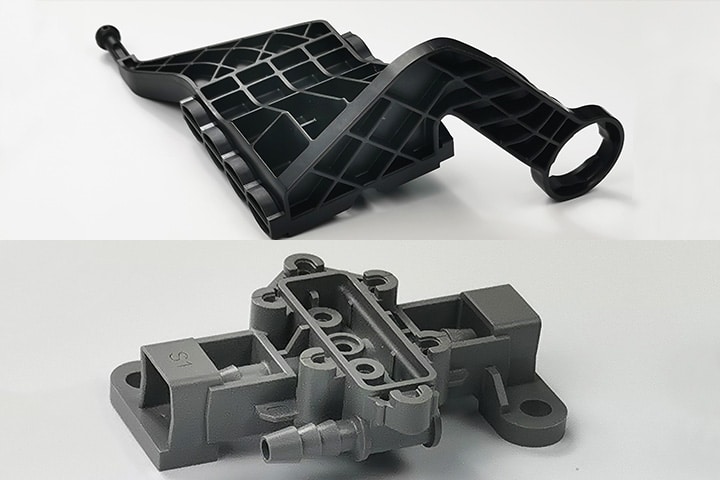

Understanding PPA: Polyphthalamide, commonly known as PPA, is a high-performance engineering plastic renowned for its excellent thermal stability, chemical resistance, and mechanical strength. As a semi-crystalline thermoplastic, PPA finds its applications in diverse sectors, ranging from automotive and electronics to industrial manufacturing.

Key Properties of PPA:

- Thermal Stability: PPA boasts impressive thermal stability, making it suitable for applications that require exposure to high temperatures. This property positions PPA as a preferred choice for components in the automotive industry, such as under-the-hood parts and electrical connectors.

- Chemical Resistance: The chemical resistance of PPA makes it ideal for use in harsh environments where exposure to chemicals and solvents is inevitable. This quality extends the lifespan of PPA components in various industrial settings.

- Mechanical Strength: PPA exhibits exceptional mechanical strength, ensuring that components made from this material can withstand heavy loads and maintain structural integrity over time. This attribute is particularly advantageous in industries where durability and reliability are paramount.

Applications of PPA:

- Automotive Industry: PPA finds extensive use in the automotive sector for the production of components like fuel system parts, brake system components, and electrical connectors, where its thermal stability and mechanical strength shine.

- Electronics: In the electronics industry, PPA is a preferred choice for manufacturing connectors, sockets, and other components that demand high-temperature resistance and reliability.

- Industrial Manufacturing: PPA’s chemical resistance and mechanical strength make it valuable in industrial manufacturing, where it is employed in the production of various components, including gears, bearings, and bushings.

Kinggor Plastic Co., LTD professional custom engineering plastics. high temperature nylon and special plastics.

Provide enhanced, flame retardant, weather resistance, temperature resistance and other application of plastic resin customization.

Custom PPA (Polyphthalamide), please contact us

PPA-1

1

PPA-ET1001L

Non-impact modified injection molding grade internal and external lubrication

2

PPA-HTN-FE8200

Non-reinforced high-impact modified injection molding grade internal and external lubrication

3

PPA-AS-1133HS

Thermal stable glass fiber reinforced 33% impact modified food grade glycol resistant

4

PPA-AS-4133L

Glass fiber reinforced 30% (high flow) food grade: FDA/LFCB resistant to ethylene glycol

5

PPA-AS-4133HS

Thermal stable glass fiber reinforced 30%, food grade: FDA/LFCB resistant to ethylene glycol

6

HTN-51G35HSL

Thermal stable glass fiber reinforced 35% food grade FDA/LFCB resistant to ethylene glycol

7

HTN-52G35HSL

Thermal stable glass fiber reinforced 35% food grade FDA/LFCB resistant to ethylene glycol

8

HTN.-59G55WRF

Thermal stable glass fiber reinforced 55% low warpage thin wall molding high rigidity

9

HTN-FR52IG30BL

Thermal stable glass fiber reinforced 30% bromine flame retardant.

10

HTN-FR52G30NH

Thermal stable glass fiber reinforced 30% halogen-free flame retardant.

| 序号 | Grade | 主要Characteristic及应用 |

| 1 | PPA-ET1001L | 非增强冲击性改性注塑级内外润滑 |

| 2 | PPA-HTN-FE8200 | 非增强高冲击性改性注塑级内外润滑 |

| 3 | PPA-AS-1133HS | 热稳定玻纤增强33%冲击性改性食品级耐乙二醇 |

| 4 | PPA-AS-4133L | 玻纤增强30%(高流动)食品级:FDA/LFCB耐乙二醇 |

| 5 | PPA-AS-4133HS | 热稳定玻纤增强30% 、食品级:FDA/ LFCB耐乙二醇 |

| 6 | HTN-51G35HSL | 热稳定玻纤增强35%食品级FDA/ LFCB耐乙二醇 |

| 7 | HTN-52G35HSL | 热稳定玻纤增强35%食品级FDA/ LFCB耐乙二醇 |

| 8 | HTN.-59G55WRF | 热稳定玻纤增强55%低翘曲薄壁成型高刚性 |

| 9 | HTN-FR52IG30BL | 热稳定玻纤增强30%溴系阻燃。 |

| 10 | HTN-FR52G30NH | 热稳定玻纤增强30%无卤阻燃。 |

11

HTN-WRF51G30

Teflon 15% + glass fiber 30% composite enhanced wear resistance and ethylene glycol resistance

12

PPA-HT1V-3FWA

Thermal stable glass fiber reinforced 30% food grade FDA/ LFCB resistant to ethylene glycol

13

PPA-HT1V-CF35

Low moisture absorption, carbon fiber reinforced 35% drone blades

14

PPA-HT1V-3FWA

Thermal stable glass fiber reinforcement: 30% food grade FDA/LFCB resistant to ethylene glycol

15

PPA-HT1V-4FWA

Thermal stable glass fiber reinforcement: 40% food grade FDA/LFCB resistant to ethylene glycol

16

PPA-HT1V-5FWA

Thermal stable glass fiber reinforced 50% food grade FDA/LFCB resistant to ethylene glycol

17

PPA-GV-2FWA

Thermal stable glass fiber reinforced 20% food grade FDA/LFCB resistant to ethylene glycol

18

PPA-GV-5FWA

Thermal stable glass fiber reinforced 30% food grade FDA/ LFCB resistant to ethylene glycol

19

PPA-GV-5FWA

Thermal stable glass fiber reinforcement: 40% food grade FDA/LFCB resistant to ethylene glycol

20

PPA-GV-5FWA

Thermal stable glass fiber reinforced 50% food grade: FDA/LFCB resistant to ethylene glycol

| 序号 | Grade | 主要Characteristic及应用 |

| 11 | HTN-WRF51G30 | 铁氟龙15% +玻纤30%复合增强耐磨性耐乙二醇 |

| 12 | PPA-HT1V-3FWA | 热稳定玻纤增强30%食品级FDA/ LFCB耐乙二醇 |

| 13 | PPA-HT1V-CF35 | 低吸湿,碳纤增强35%无人机叶片 |

| 14 | PPA-HT1V-3FWA | 热稳定玻纤增强:30%食品级FDA/LFCB耐乙二醇 |

| 15 | PPA-HT1V-4FWA | 热稳定玻纤增强:40%食品级FDA/LFCB耐乙二醇 |

| 16 | PPA-HT1V-5FWA | 热稳定玻纤增强50%食品级FDA/ LFCB耐乙二醇 |

| 17 | PPA-GV-2FWA | 热稳定玻纤增强20%食品级FDA/ LFCB耐乙二醇 |

| 18 | PPA-GV-5FWA | 热稳定玻纤增强30%食品级FDA/ LFCB耐乙二醇 |

| 19 | PPA-GV-5FWA | 热稳定玻纤增强:40%食品级FDA/LFCB耐乙二醇 |

| 20 | PPA-GV-5FWA | 热稳定玻纤增强50%食品级:FDA/LFCB耐乙二醇 |