Unlocking the Potential of Polytetrafluoroethylene (PFA): A Comprehensive Guide

Introduction: Polytetrafluoroethylene (PFA) is a versatile and high-performance fluoropolymer that has revolutionized various industries. In this comprehensive guide, we will delve into the unique properties and wide-ranging applications of PFA. Whether you’re an industry professional, researcher, or simply curious about advanced materials, this blog post aims to provide valuable insights into the world of Polytetrafluoroethylene.

- Understanding Polytetrafluoroethylene (PFA): Polytetrafluoroethylene, commonly known as PFA, is a type of fluoropolymer with exceptional thermal and chemical resistance. Its unique molecular structure makes it an ideal material for various applications, ranging from industrial processes to consumer products.

- Key Properties of PFA: Explore the unparalleled properties of PFA, including its non-stick surface, excellent electrical insulation, and resistance to extreme temperatures. We’ll break down these characteristics, shedding light on why PFA stands out in comparison to other materials in the market.

- Applications Across Industries: From aerospace and electronics to healthcare and manufacturing, discover how PFA is making a significant impact across diverse industries. Learn about its role in creating durable and reliable components for critical applications, contributing to advancements in technology and efficiency.

- Advantages of PFA in Manufacturing: Businesses seeking high-performance materials for their manufacturing processes will find valuable insights here. We’ll discuss the advantages of incorporating PFA into production, emphasizing its ability to enhance product longevity, reduce maintenance costs, and improve overall operational efficiency.

- PFA in Everyday Products: Unbeknownst to many, PFA plays a crucial role in everyday products that we often take for granted. Explore how this remarkable material contributes to the functionality and safety of cookware, electrical insulation, and various other consumer goods.

- Future Trends and Innovations: Stay ahead of the curve by exploring the latest trends and innovations in the world of Polytetrafluoroethylene. Discover how ongoing research and development are pushing the boundaries of what is possible with PFA, opening up new possibilities for industries around the globe.

- Choosing the Right PFA Products: For those looking to integrate PFA into their processes, we provide practical advice on selecting the right PFA products. Considerations such as specific application requirements, industry standards, and supplier reputation are essential factors to ensure optimal performance.

Polytetrafluoroethylene (PFA) is a thermoplastic fluoroplastic, similar to polytetrafluoroethylene (PTFE), but has better processing properties. The following are some of the main properties and applications of PFA materials:

performance:

Chemical resistance: PFA has excellent chemical resistance and is stable to most chemicals, including acids, bases, solvents, etc.

Heat Resistance: PFA has very good heat resistance and is able to operate over a wide temperature range, typically between -200°C and 260°C.

Non-adhesion: Similar to PTFE, PFA also has excellent non-adhesion properties, making it very effective in applications with high adhesion requirements.

Electrical Insulating Properties: PFA is a good electrical insulating material and is suitable for electrical and electronic applications.

Aging resistance: PFA material has excellent aging resistance and can maintain its physical and chemical properties for a long time.

Mechanical properties: PFA has good mechanical properties, including tensile strength, flexural strength and impact strength.

application:

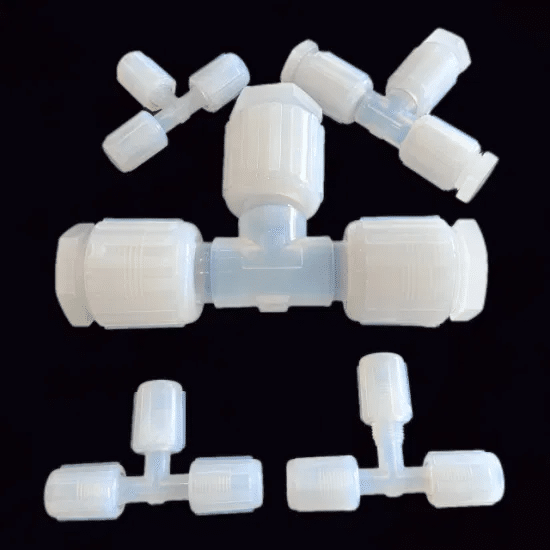

Chemical Processing Equipment: PFA is widely used in manufacturing chemical processing equipment such as pipes, valves, pumps, etc. due to its ability to resist various corrosive chemicals.

Electronics and Electrical Applications: Due to its good electrical insulation properties, PFA is often used in the manufacture of cables, connectors and other electrical components.

Food and medical devices: PFA is an FDA-approved food-grade material that can be used to manufacture food processing equipment and medical devices.

Liquid transfer systems: PFA pipes and fittings are commonly used in liquid transfer systems, such as in laboratories, semiconductor manufacturing and other fields.

Coatings and Sealing Materials: PFA can be used in coatings and sealing materials to provide chemical and heat resistance.

Automotive industry: In automobile manufacturing, PFA is used as parts with strict requirements on high temperature resistance and chemical properties, such as automobile wiring harness insulation.

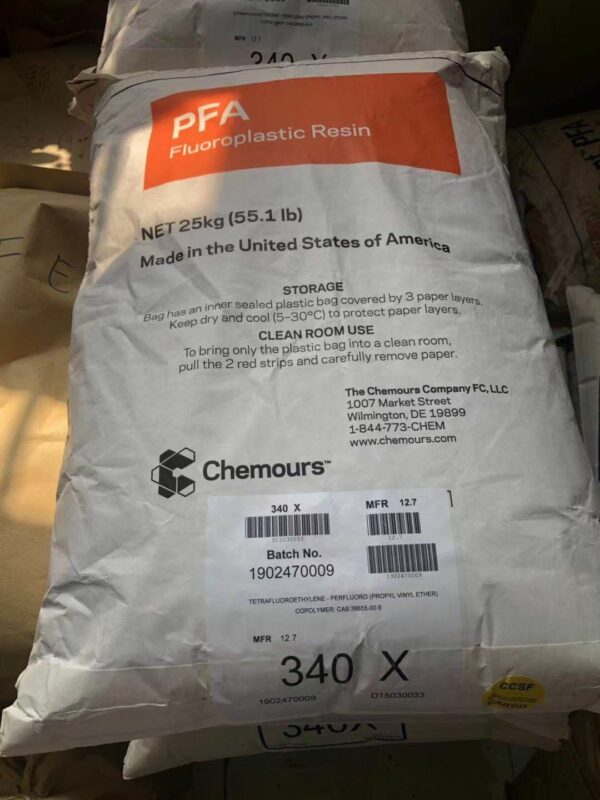

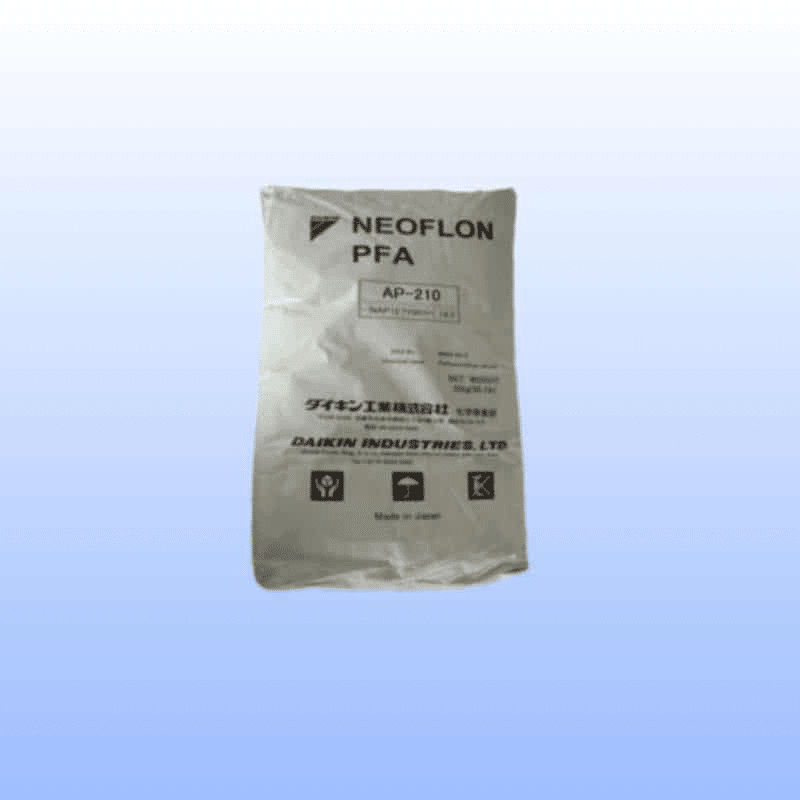

PFA(PerfluoroAlkoxy)Manufacturer:

PFA(PerfluoroAlkoxy)

DuPont

3M

Solvay

Chemours

Common PFA(PerfluoroAlkoxy)models:

PFA AP-210AS

PFA 416HPX

PFA AP-211SH

PFA AP-201SH

PFA MP102(粉)

PFA 945HP

PFA P-73PT

PFA MFA 1041

PFA TE9724

PFA 416HPX

PFA MP-102

PFA AP-215SH

PFA 950HP

PFA TE-7043

PFA P-63P

PFA M640

PFA AP-201(2)

PFA AP-221SH

PFA AP-230AS

PFA JD-25

PFA TE9725

PFA J-340 BK

PFa P-76P

PFA 450HP

PFA P-61XP

PFA P-65P

PFA AP-230ASL

PFA C-5200

PFA PF860

PFA 350X

PFA 340X

PFA P-63PT

To purchase PFA(PerfluoroAlkoxy) or get PDF files, please contact us