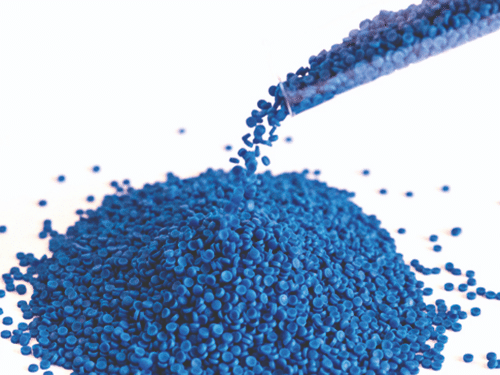

Elastomer material TPV, TPU, TPR, TPE, EVA, POE material selection guide

Classification

Can be divided into two categories: thermosetting elastomers and thermoplastic elastomers.

Thermosetting elastomer, that is, rubber in the traditional sense (Rubber)

Thermoplastic elastomer, abbreviated as TPE, has been used in more and more commercial applications since the 1990s. This classification also shows that rubber is processed by thermoset equipment in two different ways, and TPE is processed by thermoplastic equipment.

Humans usually call thermal solid elastomers, that is, traditional rubbers such as styrene-butadiene rubber, butadiene rubber, and silicone rubber, which are rare styrene-butadiene elastomers, butadiene elastomers, or silicone elastomers. For thermoplastic elastomers, it is often called polyurethane elastomers, SBS elastomers, and POE elastomers, etc. This is one of the reasons why most people confuse the concept of elastomer and rubber.

thermoplastic elastomer

Thermoplastic elastomer (thermoplastic elastomer, TPE) is defined as: exhibit rubber elasticity at room temperature and plasticize polymer materials at high temperature. Therefore, this polymer has some properties of thermoplastic rubbers and thermoplastics. The basic structural feature of a thermoplastic elastic polymer chain is that it connects, or connects, some chemical species in series to form distinct plastic segments (hard segments) and rubber segments (soft segments). The force between the hard segments is sufficient to condense into microdomains (such as glass microdomains or crystalline microdomains), forming physical crosslinks between molecules. The soft segment is the higher-end segment with greater spin capacity.

Thermoplastic elastomers are an important part of elastomers. The common ones are as follows:

Styrene thermoplastic elastomer

Styrene block copolymer thermoplastic elastomer is the earliest thermoplastic elastomer studied, mainly including SBS, hydrogenated SBS (SEBS), SIS and hydrogenated SIS. It is the largest and fastest-growing thermoplastic elastomer in the world. From an application standpoint, styrenic thermoplastic elastomers are of most interest for properties similar to vulcanized rubber at room temperature. In addition, its elastic modulus is very high and does not vary with the relative molecular mass. Styrene thermoplastic elastomer has the characteristics of high strength, softness, small rubber elasticity and small permanent deformation, and is widely used in shoes, plastic modification, asphalt modification, waterproof coating, liquid sealing material, wire, cable, auto parts, medical treatment Equipment parts, household appliances, office automation, adhesives and other fields. The biggest problem of SBS and SIS is that they are not heat-resistant, and the operating temperature generally does not exceed 80°C. At the same time, its strong elongation, weather resistance, oil resistance and abrasion resistance cannot be compared with rubber. Modified hydrogenated SBS (SEBS) and hydrogenated SIS, the performance in practical applications is much higher than that of ordinary linear and star SBS, and the service temperature can reach 130°C, especially with excellent ozone resistance, oxidation resistance, ultraviolet resistance and weather resistance It is comparable to ethylene-propylene rubber in non-dynamic applications.

polyurethane thermoplastic elastomer

Polyurethane thermoplastic elastomer (TPU) average relative molecular weight is generally 600 ~ long chain polyol (polyether or polyester) relative molecular weight is 61 ~ linear polymer material polymerization 400 chain extender and polyisocyanate. The long-chain polyol (polyether or polyester) in the main chain of TPU macromolecules constitutes the soft segment, which mainly controls its low temperature performance, solvent resistance and weather resistance, while the chain extender and polyisocyanate constitute the hard segment. Since the ratio of hard and soft segments can be adjusted in a wide range, thermoplastic polyurethane can not only be a soft elastomer, but also a brittle high-modulus plastic, and can also be made into films, fibers, and the only variety that TPE can do .

TPU has excellent abrasion resistance, oil resistance and cold resistance, and has sufficient resistance to oxygen, ozone and radiation. At the same time, as an elastomer, it has high tensile strength and elongation at break, and has excellent properties such as small compression set and large bearing capacity. TPU has been widely used in many fields of the national economy such as shoemaking industry, medical and health care, clothing fabrics, and national defense supplies, but its disadvantages are poor aging resistance, low coefficient of friction on wet surfaces, and easy slipping. TPU is very polar. During processing, when the shearing effect is strong, it is easy to generate heat inside, resulting in degradation. Melt viscosity is strongly dependent on temperature. Small changes in temperature will result in sharp changes in viscosity. Therefore, the processing temperature range is narrow, the cost is high, and the price is expensive, which further limits the popularization and application of TPU.

‘Elastomeric material’

Polyolefin thermoplastic elastomer

Polyolefin thermoplastic elastomers (TPO) mainly include block copolymers, graft copolymers and blends, including polyolefin thermoplastic elastomers ethylene-octene copolymers synthesized by metallocene catalysts (POE) thermoplastic dynamic vulcanizates are two A major polyolefin thermoplastic elastomer.

- Metal polyolefin elastomer ethylene-traditional octene copolymer metallocene catalyst Ziegler-Natta Compared with the catalyst, it has an ideal single active center, which can precisely control the relative molecular mass distribution, comonomer content and its distribution on the main chain distribution and crystal structure. Synthetic polymers are high-stereoregular polymers with a very narrow relative molecular weight distribution, which can accurately control the physical and mechanical properties and processing properties of polymers. Polyolefin thermoplastic elastic ethylene-octene copolymers (POE) synthesized by metallocene catalysts On the one hand, narrow molecular weight, short distribution, excellent physical and mechanical properties (high elasticity, high strength, high elongation) and good low temperature performance. Due to the saturation of the molecular chain, the uncle’s carbon atoms are relatively few, and it has excellent heat resistance and UV resistance. The thermal stability, optical properties and cracking resistance of POE are better than EVA, better than SBS weathering resistance, the embrittlement temperature is lower than -76°C, the toughness and ductility are still good at low temperature, and the shear property of POE is good, which is beneficial to High-speed extrusion and molding with little or no plasticizer required for long life. The physical and mechanical properties, chemical resistance and ozone resistance of POE materials can be approached by peroxide, silane and radiation crosslinked EPDM; heat aging resistance and UV aging resistance are better than EPDM and EPM, so POE is more suitable for outdoor use, POE The permanent thermal compression deformation is smaller than that of EPDM. POE rubber or plastic can be modified as a modifier. The processing temperature of POE is low, and it is easier to mix with non-polar rubber, especially EPR, EPDM, NR, SBR and BR. The largest application of POE is plastic products. POE modified PP greatly improves the impact strength of the notch; after maleic anhydride grafted POE, the elastomer is used to modify PA6, which can reduce the hygroscopicity of the material and greatly improve the impact strength.

- Thermoplastic dynamic vulcanizate The thermoplastic elastomer made by dynamic vulcanization is called thermoplastic vulcanizate (TPV). TPV is a thermoplastic elastomer (TPE) special segment copolymer consisting of elastomer-thermoplastic polymer blends with better properties than simple blends. The key technology for preparing thermoplastic vulcanizate is dynamic vulcanization technology. One of the advances in this technology is the preparation of low-cost existing processing methods by blending existing polymers. The process also meets the environmental requirements of large polymer plants, compared to conventional high capital investment intensive production of new materials. Other block copolymers of TPV technology have advantages over thermoplastic elastomer sources: high upper temperature limit, resistance to hydrocarbon media and low compression set.

thermoplastic elastomer polyamide

Thermoplastic Elastomer Polyamide (TPEA) It consists of high melting point crystalline polyamide hardness and non-crystalline polyester or polyether satin. According to the raw materials required for the synthesis of polyamide thermoplastic elastomers, the synthesis methods can be divided into dibasic acid method and isocyanate method. Using the dibasic acid method, T PAE prepares carboxyl-terminated aliphatic polyamide blocks and hydroxyl-terminated polyether diols through esterification. The isocyanate method uses semi-aromatic amide as the hard segment and aliphatic polyester, polyether or polycarbonate as the soft segment. Using the isocyanate method, the semi-aromatic amide hard segment is prepared by the reaction of aromatic diisocyanate and dicarboxylic acid, instead of the traditional polymerization of diamine and dibasic acid, ring-opening polymerization of cyclic lactam or reaction of diamine and dibasic acid chloride . In contrast, the former avoids the problems of low activity of aromatic diamines, difficulty in obtaining aromatic cyclic lactam monomers and release of corrosive hydrogen chloride.